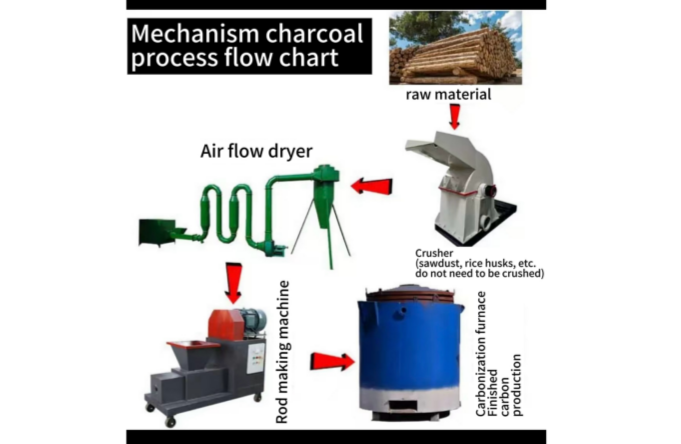

The charcoal making equipment can make sawdust or agricultural waste into carbon rods of different diameters and shapes. The charcoal making machine is designed with an automatic temperature control system and can produce high-density carbon rods from biomass, trees, bamboo, etc. The carbon rods made can be used as fuel for barbecue, heating, household boilers or industrial boilers.

1. Crusher. Crush wood, bamboo, etc. into chips.

2. Dryer. Reduce the moisture content of the raw materials from 20%~50% to 8%~12% (the best moisture range for rod making) to prevent cracking or incomplete combustion

3. Rod making machine. Press the dried wood chips under high pressure (50~300MPa) into cylindrical rods (such as fuel rods, charcoal rods) with a density ≥1.0g/cm³

4. Carbonization furnace. Pyrolysis of wood materials in a high-temperature, oxygen-deficient environment to generate high-value-added biochar, while producing combustible gas (wood gas) and wood vinegar as by-products

https://youtube.com/shorts/zbR9SGHBDjA?si=ii_YiPRfcuSJxOCF

|

Items |

Output |

Dimension | Weight | Power |

| Crusher | 500kg/h | 1.4*0.8*0.8m | 500kg | 11kw |

| Dryer | 500kg/h | 1.9*1.22*1.65m | 700kg | 4.5kw |

| Rod making machine | 200-300kg/h | 2.02*0.87*1.5m | 700kg | 22kw |

| Carbonization | 500-1000kg/day | 1.8*1.7*2.2 | 800kg | / |

If you have any questions, feedback or comments, please fill out the form below and we will reply you back as soon as possible.