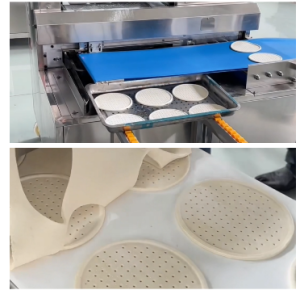

The commercial fully automatic pizza making machine is an efficient, precise and intelligent equipment designed for commercial catering places. It integrates advanced mechanical engineering technology and intelligent control system, and aims to provide fast, high-quality and stable pizza making solutions for restaurants, pizza chains, food processing plants, etc., greatly improving the production efficiency of pizza making, reducing labor costs, and ensuring product consistency and standardization.

| ITEMS | DESCRIBE |

| Voltage | 220v |

| Power | 6kw |

| weight | 280kg |

| Output | 60-100Pieces/min |

| Size | 380cm*60cm*120cm |

If you have any questions, feedback or comments, please fill out the form below and we will reply you back as soon as possible.